Byron Jackson, IDP, Worthington, United Centrifugal, Wilson-Snyder, Pacific

Applications:

Hydrocarbon Processing, Lubricating Oil, High Temperature Service, Hydrocarbon Booster, General Purpose, Gas Industry Service , Gas Production, Fuel, Flammable Liquids, Diesel Fuel, Boiler Circulation, Water, Synthetic Fuels, Petroleum Distribution, Petrochemical Processing, Lube Oil Transfer and Feed, Gasoline, Light Oils, Petroleum Production and Refining

Industries:

Crude Handling and Treatment, Catalytic Cracking, Hydrocraking, Utilities, SAGD, NGL, Delayed Coking, LNG, Hydrotreating, Water Handling and Treatment, Gas Treatment, Gas-to-Liquids, Distillation, Logistics and Tank Farm

Standards:

API610

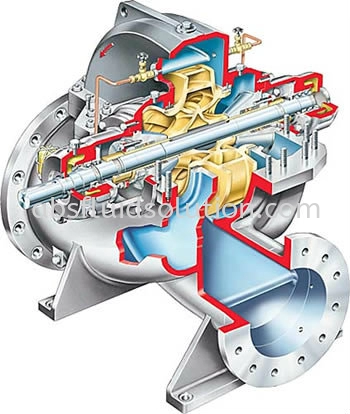

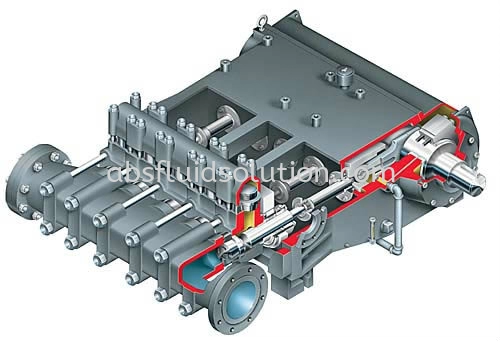

Space Saving Design engineered for safe, reliable performance in cryogenic, high temperature and high working pressure services.

API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services. A full complement of API 610 seal flush plans is available.

Stiff Shaft Design limits maximum deflection at seal faces to 0.05 mm (0.002 in). Shaft stiffness factors (L3/D4) are best in the industry.

Dynamically Balanced Impeller limits vibration and ensures smooth operation over wide flow range.

Accommodates NEMA, IEC and existing field drivers (C-face and P-base).

Features:

-

Bearing lubrication options

- Oil cascade

- Oil mist

- Grease lube

-

Options

- Inpro top bearing isolator

- Inducer for low NPSH requirements

- Double suction impeller

-

Other configurations

- HWM (OH3, low flow, high head, single stage)

- HWM-2 (OH3, low flow, high head, 2-stage)

-

Operating parameters

- Flows to 1500 m3/h (6600 gpm)

- Heads to 300 m (1000 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures from -160°C (-250°F) to 400°C (750°F)

Inquiry - HWX API 610 (OH3), Overhung, Vertical In-Line Pump