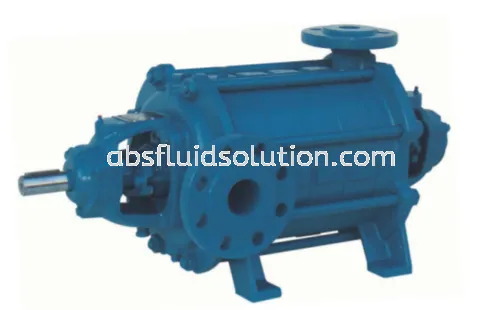

The SIHImulti pumps are horizontal multistage centrifugal pumps of ring-section design, which meet the technical requirements of ISO 5199 / EN 25199.

Benefits: SIHImulti

• Advanced modular design reduces the number of parts while maximizing interchangeability.• Optimal selection of impeller diameter and diffuser size installed in a standardized casing ensures that the pump matches the required duty for each application.

• The first stage of each pump size is equipped with a low required NPSH suction impeller.

• Axial thrust is hydraulically balanced by a patented balanced drum system with self-adjusting throttle device.

• Generously sized angular contact ball bearings absorb residual thrust.

• The pump can be built with an axial, vertical, left or right suction and a vertical, left or right discharge in any combination.

• All pump sizes can be provided with one or more "dummy" stages, if required.

Features: SIHImulti

• The pump is driven from the discharge side and the rotor is supported on the side by grease-lubricated anti-friction bearings and on the suction side by self-adjusting sleeve bearing lubricated by the pumped liquid.• The pump feet are mounted to the suction and discharge casings in such a manner that the suction casing (for suction casings with radial branch) and discharge casing can be swung to suit the installation conditions.

• Casing components are sealed by O-rings and held together with tie rods.

• The balancing line is returned to the suction casing or to the upstream vessel.

• The mechanical shaft seal is located on the drive side only. Sealing can be (cooled or uncooled) single acting mechanical seal, packed gland (cooled or uncooled) or double-acting mechanical seal (uncooled).

Technical Data:

| Flow rate | max. 1100 GPM (250 m³/h) |

| Head | max. 2067 feet (630 m) |

| Speed | max. 3600 rpm |

| Temperature | 14 to 356 F (-10 to +180°C) |

| Pressure Rating | max. 914 psi (63 bar) |

| Shaft seal |

mechanical seal packed gland |

Industries:

- Power

- Water & Wastewater Treatment Plants

- Irrigation

- Chemical & Process

- Pharmaceutical

- Food

- And many More

Applications:

- Boiler feed

- Condensate systems

- Pressure boosting

- Irrigation

- High pressure cleaning

- Heating

- Waterworks, and water supply

- Reverse osmosis

- Chemical and Process

- And many more ...

Inquiry - MS Series - Modular Multistage Pump