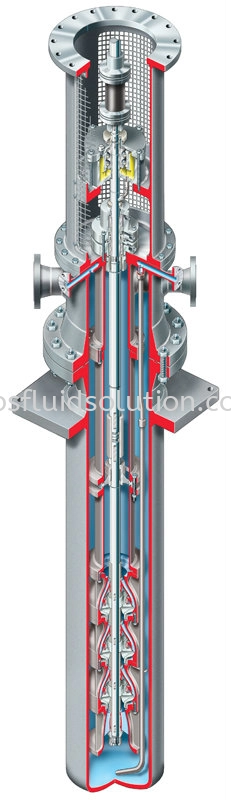

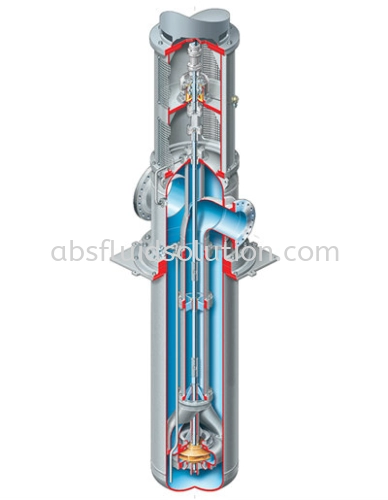

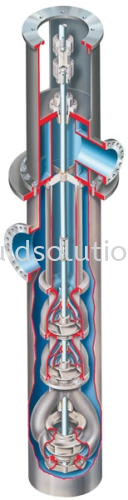

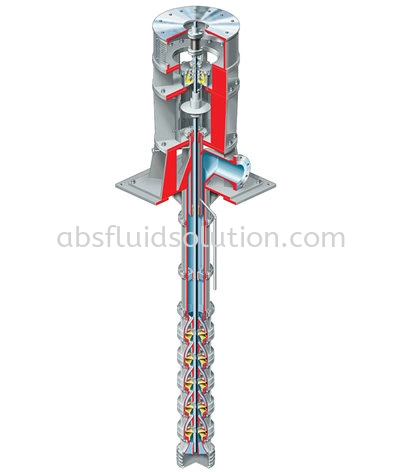

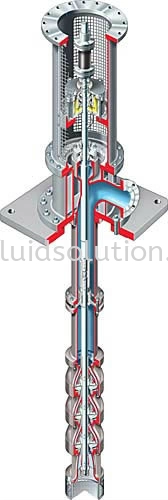

WUC ISO 13709/API 610 (VS6) Vertical, Double Case, Multistage Pump

Category: Vertical Pumps

Quantity: In Stock

Worthington

Applications:

Acid Transfer, Catalytic Cracking, Condensate Extraction, Crude, Product and CO2 Pipeline, Dewatering and Water Supply (mining), Water Treatment, Hydrocracking, Hydrotreating, Industrial Gases, LNG, Snowmaking, Distillation (oil and gas)

Industries:

Power Generation, Water Resources, Oil and Gas, General Industries, Mining, Chemical Processing

Standards:

API682, API610

Flanged Spacer Type Coupling permits easy maintenance of thrust bearings and mechanical seals without disturbing or removing driver.

Separate Axial Thrust Bearing Assembly designed to withstand total hydraulic thrust and rotor weight.

ISO 21049/API 682 Compliant Mechanical Seal Chamber accommodates all cartridge mounted seal designs, including: single and dual pressurized or unpressurized liquid; and gas designs.

Screen-Type Non-Sparking Coupling Guard provides safety while allowing visual inspection of coupling and mechanical seal areas.

Casing and Impeller Wear Rings feature a minimum 50 Brinell hardness difference between them. These rings prevent galling, allow economical retention of operating efficiency and maintain mechanical stability.

Operating Parameters

- Flows to 3000 m3/h (13 200 gpm)

- Heads to 2000 m (6560 ft)

- Pressures to 200 bar (2900 psi)

- Temperatures from -200°C (-328°F) to 350°C (660°F)

Inquiry - WUC ISO 13709/API 610 (VS6) Vertical, Double Case, Multistage Pump