Brands:

Flowserve

Applications:

Petroleum Production and Refining, Decoking

Industries:

Heavy Oil and Upgrading, Delayed Coking

Flowserve

Applications:

Petroleum Production and Refining, Decoking

Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

- Two flange sizes – The rotary joint is available with 125 mm (5 in) 250 PN (1500 lb) or 400 PN (2500 lb) inlet flanges and with optional 150 mm (6 in) Unibolt® or compact flange connections to match the drill stem connector

- Cast single-piece gooseneck eliminates welds and reduces corrosion

-

Rotary joint drive options –

- Air piston motor

- Hydraulic

- E-motor (with VFD)

-

Dual Seal

- Increased reliability with a four-year design life

- Switching from the primary seal to the secondary seal allows for planned maintenance in the event of a seal failure

- Simple installation reduces downtime

- Retrofit option for all Flowserve rotary joints

-

Rotary joint upgrade options

- Convert packing to seal rings

- Convert vertical air motor to horizontal motor with right angle gear

- Upgrade Unibolt coupling to direct connect with drill stem

- Add second bearing for right angle drive shaft

- Convert to integral gooseneck and support cage

- Add rotary joint stiffeners

Operating Parameters

Two models available:

-

Pressures to

- 205 bar (3000 psi)

- 430 bar (6230 psi)

- Speeds of 2 to 17 rpm

- Rotates 30 m (100 ft) to 45 m (140 ft) drill stem lengths

- Carries axial hydraulic loads in the magnitude of 190 000 J (140 000 ft-lb) through its main thrust bearing

- Seals hydraulic pressure against atmosphere

®Unibolt is a registered trademark of Cameron International Corporation

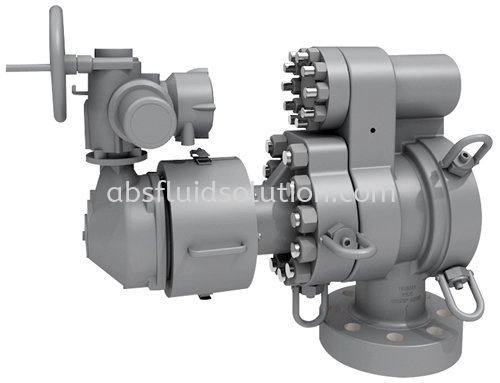

Inquiry - Hydraulic Decoking Systems Rotary Joint