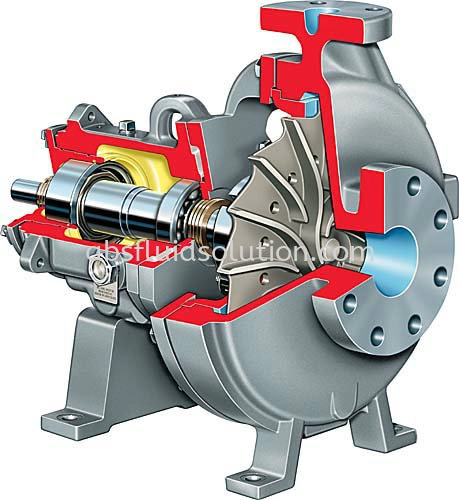

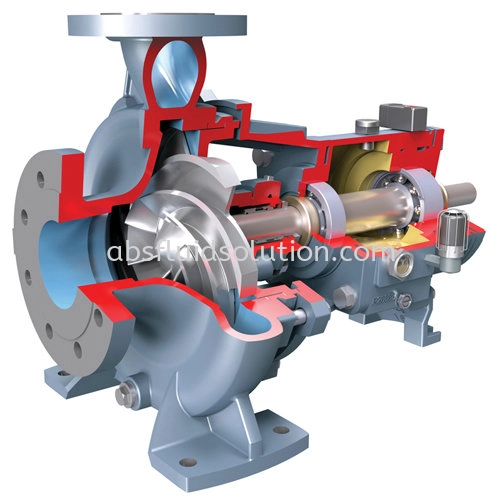

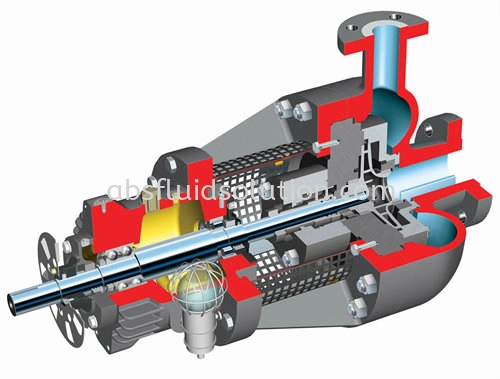

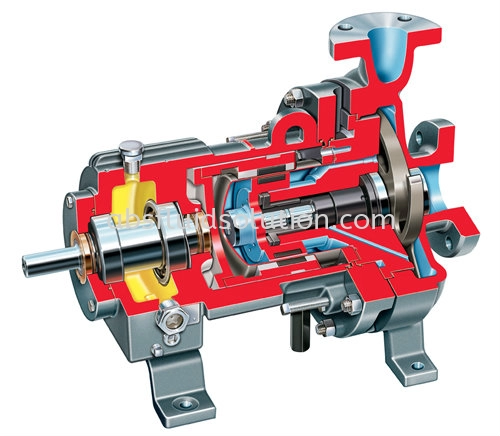

Durco Mark 3 ISO Overhung, Chemical Process Pump

Category: Over Hung / End Suction Pump

Quantity: In Stock

Durco

Applications:

Coatings (pulp and paper), Nuclear Service, Construction, Offsites and Waste Treatment, Cooling Water (metals), Pharmaceuticals, Desalination, Plating, Galvanizing and Other Coatings, Dewatering and Water Supply (mining), Polymers, Drilling and Production, Renewable Fuel Production, Electronics, Sewage Collection and Treatment, FPSO, Shipping, Acid Transfer, Food Processing, Slurry Processing, Agriculture, Gas Treating and Sulfur Recovery, Solvents, Automotive, HVAC, Volatile Organic Compounds, Auxiliary (chemical), Heavy Oil, Oil Sands and Shale, Hydraulic Press (metals), Waste Processing, Auxiliary Services (power), LNG, Water Supply and Distribution (water), Bleach Chemical (pulp and paper), Leaching Acid, Water Supply and Treatment (oil and gas), Caustic and Chlor-alkali, Water Treatment, Chemical and Liquor (pulp and paper), OEM

Industries:

Chemical Processing, General Industries, Mining, Water Resources, Power Generation, Primary Metals, Pulp and Paper, Oil and Gas

Standards:

ISO

Heavy-duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads and improves reliability.

Reverse Vane Impeller is the only impeller design that offers repeatable pump performance throughout the life of the pump. Open impellers are available.

SealSentry™ Seal Chamber extends seal life and provides advanced self-flushing capability.

Two-piece, Ductile Iron Bearing Housing is designed for safety, strength, interchangeability and retrofit capability.

External Micrometer Impeller Adjustment Mechanism accurately sets impeller clearance in 20 seconds, in the shop or the field.

IPS Beacon power end condition monitor provides a visual signal that a current or past alert condition has occurred.

Back Pull-out Design allows removal of rotating element without removing casing, piping or motor.

Operating Parameters

- Flows to 1400 m3/h (6160 gpm)

- Heads to 220 m (720 ft)

- Pressures to 25 bar (365 psi)

-

Temperatures from -80°C (-110°F) to 400°C (752°F)

Inquiry - Durco Mark 3 ISO Overhung, Chemical Process Pump