PL series pumps have been specially designed to make dismantling (whether for inspection, cleaning and maintenance) quicker and easier. The forward seal position places the seals in direct contact with CIP fluides. Superior seal cleanlines lengthens seal life and minimizes seal flaking (prodcts contaminations). Because the seals are located directly behind the rotors, areas of product entrapment are eliminated for superior hygienic performance.

Unique front loading seal design gives faster maintenance, easier cleaning and less downtime. The only dismantling front cover, the rotors and seals are take out without pump dismantling from pipe.

PL series pumps have been working to suit all hygienic pumping applications in the food, diary, beverage, pharmaceutical and another places where the stainless steel is resistant to liquids to be pumped.

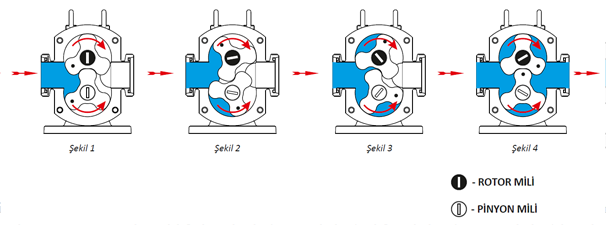

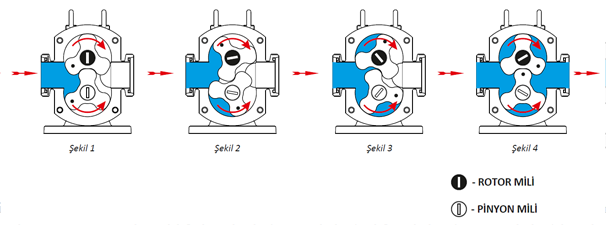

PL series pumps are positive displacement pumps. The volume at the inlet increased when the rotors rotate and the product is drawn into the pump. It is then transported in the space between the lobes and the periphery of the pump housing to the discharge side. The volume between the rotors are reduced here and the product in forced out through the outler.

Unique front loading seal design gives faster maintenance, easier cleaning and less downtime. The only dismantling front cover, the rotors and seals are take out without pump dismantling from pipe.

PL series pumps have been working to suit all hygienic pumping applications in the food, diary, beverage, pharmaceutical and another places where the stainless steel is resistant to liquids to be pumped.

|

|

Max. Capacity: 100 m³/h | |

|

|

Max. Diffr. Pressure: 20 bar | |

|

|

Max. Viscosity: 440.000 cSt | |

|

|

Temperature Range: 0 to +150 °C

*Higher temperature is available up to 200 °C with special production

|

Features

- The revolutionary, EHEDG and 3A certified

- The lobe type can be applied with single wing, bi-wing, tri lobe and multi lobe according to application. The all rotor types can be changed without any additional tools or clearance.

- Operating wide range of viscosity

- Easy of usage and maintenance with only two moving parts

- Unique front loading design

- A Single seal which can be modified to a double type (flushing) with minimum of additional parts.

- Horizontal ports which can be fitted vertical simply

- It is suitable to drive clockwise / counter clockwise direction

- The wetted parts are AISI 316 / 316L quality

- The inlet port can be rectangular for high viscosity application to feed well

- The special designed rotor types allows some pieces inside the liquid

Options

- Heating / Cooling jackets can be applied to pump cover or casing

- Can be applied Single, Double or Lip seal

- Vertical connection options

- Single Wing, Bi-Wing, Tri Lobe, Multi Lobe options

- Relief valve can be applied to pump cover

- Connections according to optional standard DIN 11851, Tri-Clamp,, SMS and flange connection

Working Principle

PL series pumps are positive displacement pumps. The volume at the inlet increased when the rotors rotate and the product is drawn into the pump. It is then transported in the space between the lobes and the periphery of the pump housing to the discharge side. The volume between the rotors are reduced here and the product in forced out through the outler.

Inquiry - PL series